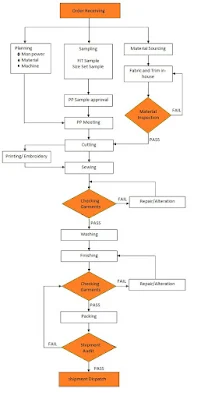

Bulk production flow chart for woven and cut & sew knitwear garments industry manufacturing process.

Taking notes for my understanding or future references about - BULK PRODUCTION FLOW CHART FOR WOVEN AND CUT & SEW KNITWEAR GARMENTS INDUSTRY MANUFACTURING PROCESS.

If there are any corrections, please leave your suggestions.

BULK PRODUCTION FLOW CHART FOR WOVEN AND CUT & SEW KNITWEAR GARMENTS INDUSTRY MANUFACTURING PROCESS.

MARKER PLANNING (BY SELECTING MARKER TYPE)

↓

MARKER MAKING (MARKER LENGTH & WIDTH SELECTION)

↓

FABRIC SPREADING (SPREAD FABRICS ONTO CUTTING TABLE)

↓

MARKER PAPER SET ON LAYING FABRIC FOR CUTTING

↓

NUMBERING

↓

SEWING PRODUCTION PLANNING (FOR SEWING ROOM)

↓

EMBROIDERY, PRINTING, DELAMINATING, SHAPING ETC (IF REQUIRED)

↓

FUSIBLE INTERLINING PASTE IN DIFFERENT PARTS (IF NECESSARY)

↓

SEALING / ASSEMBLING

↓

WELDING, BONDING, SEAM SEALING (ALTERNATIVE TO SEWING)

↓

IN-HOUSE PRODUCTION PLANNING DEPENDS ON THE SEWING ROOM / FLOOR

↓

WASHING

↓

PRODUCT FINISHING, PRESSING & PACKAGING

- PRIMARY

- SECONDARY

- MASTER

↓

PRE-FINAL & FINAL INSPECTION / QUALITY AUDIT

↓

DISPATCH / SHIPMENT TO CUSTOMER

By following the above-mentioned steps or procedures a Bulk production flow chart for woven and cut & sew knitwear garments industry products is ready for forwarding to the market or port for shipment.

Comments

Post a Comment